|

THE WORKFORCE

While the Gasworks was in course of construction, much other work

was proceeding in the background to do with setting up the Company,

organising its day-to-day administration and deciding on what price

to charge for gas, especially to large consumers. While it is beyond

the scope of this account to set out details of the Company’s

workforce during the century covered by its Minute Books,

some mention of the Company organisation during its

early years is appropriate.

THE BOARD: at

Shareholder and Director meetings held on the 25th April, 1850, the

various positions required for the administration of the new Company

were filled by election, namely Thomas Butcher and John Brown,

Trustees; Messrs. H. S. Rowbotham, Frederick Butcher, William

Brown, Edward Pope and Joseph Gurney, Directors; William

Brown, Chairman of Directors and Edward Pope, Vice

Chairman; John Chapman and Thomas Woodman, Auditors;

Thomas Butcher, Treasurer; Messrs Butcher and Son, Bankers;

and A. T. Parkes, Secretary, at the time the only remunerated

officer of the Company at a salary of £12 p.a.

Board members came and went over the years, and until the Company

was sold in 1930, most were well known local businessmen. Among

their number William Brown (auctioneer and land surveyor), George

Butcher (of the Tring banking family), Walter Mead (butcher and farmer)

and John Clement (watch and clock maker) each, in their turn, chaired

the Board for many years.

COMPANY SECRETARY:

the first Secretary to be appointed was Alexander Thomas Parkes,

agent of the Tring Park Estate. He was described in his

obituary (Bucks Herald, 15th September 1888) as “excellent

man of business, kind in all relations of life, just, methodical,

and great worker.” Parkes was succeeded by Frederick Gotto

who remained in post until May 1861, when he was succeeded by John

Amsden at a salary of £30 p.a. At the Board meeting for that

month the directors resolved “that he be required to enter into a

bond jointly with a respectable person in the sum of £150,” a

large sum for the time. Whether this requirement had applied

to earlier Secretaries or, if not, why it should apply to Amsden,

isn’t recorded. The Minute Book also lists the duties that

Amsden was required to perform:

To make the returns required by the Act of Parliament;

To register all shares the parties themselves paying for the stamp

and transfer fees;

To inspect meters, and register gas consumed whenever required by

the Board to do so;

To collect rents quarterly and pay wages to Manager at Works weekly;

To visit the Works not less seldom than six times per week on an

average [his predecessor was required to visit once a week];

To examine the Manager’s petty cash acct and to receive monies for

coke, tar, etc weekly;

To examine all accounts, send notices of meetings and undertake all

correspondence;

Travelling expenses, postages, stationery etc. etc. to be provided

and paid for by the Company.

When the various monies in the hands of the Secretary reach £15, £10

is to be paid into the bank.

|

|

|

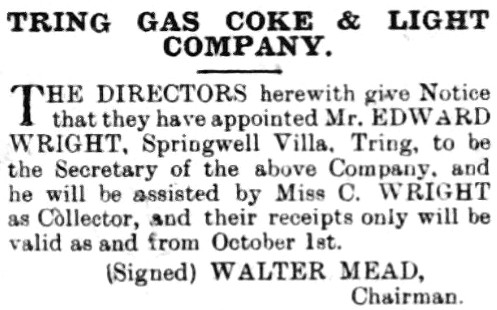

Bucks Herald, 29th

September1917. |

Amsden was to remain in post until August, 1888, when he was taken

seriously ill, dying in June of the following year. His

obituary writer described him as:

“ . . . . one of the best known men in Tring, where he was born

and had always lived. For a number of years he was Secretary of the

Gas Company, and a collector of rates, positions in which his

integrity was highly appreciated . . . . He was formerly engaged in

the [straw] plait trade, and latterly did some business as a

coal merchant. He was a man of good ability and of business

capacity, and no man in Tring, probably, knew more of its general

affairs for the last half century.”

Bucks

Herald, 22nd June 1889

WORKS MANAGER:

the first Works Manager was David Pike, appointed in January 1851 at

a wage of 16 shillings a week; he was “also to have the privilege

of putting in fittings to consumers on his own account . . . . It

was also resolved that one man be employed under Pike during the

winter months at 10s. per week wages,” the long nights of the

winter months being those in which consumption of gas was likely to

be highest. There is no indication at this time that anyone

else was permanently employed at the works, which suggests that Pike

was running the plant almost single-handed. In addition to

their wages, Works Managers received free coal, gas and

accommodation in the cottage on the site. Whether the cottage

had been built as part of the gasworks, or was pre-existing isn’t

known, but the Minutes record that in March 1852 Pike

informed the Board that “the cottage was very inconvenient and

unhealthy”. Regardless of whether that was so, the cottage

remained the Works Manager’s home until 1907, when it was replaced

by the house that stands on Brook Street today, the sole relic of

the Tring Gas Light & Coke Company.

The former gasworks site redeveloped as

'Brookside' - luxury apartments.

The house in the foreground (by Tring architect William Huckvale) was

the Manager’s house.

The longest serving Works Manager was Thomas Thompson, who was appointed

in 1862. In May, 1901, the Board resolved “that in recognition

of the long and valuable services of Mr Thompson the Manager of the

Works & because of his recent serious indisposition, he be given the

opportunity of a rest & change for 3 weeks to be prolonged one more week

if deemed advisable, also a gratuity of £10.” The Minutes

for October 1901 record that “That this Board deeply regrets the

death of Mr. T. Thompson who for upwards of 39 years was a faithful &

capable Manager of the Company’s Works.” The curious thing is

that Thompson’s surname was in fact Roberts, which is the name inscribed

on his gravestone in the New Mill Baptist Cemetery ― how he came to be

addressed as Thompson throughout his long service with the Company is a

mystery. Following Thompson’s death his son took over as Manager.

|

|

|

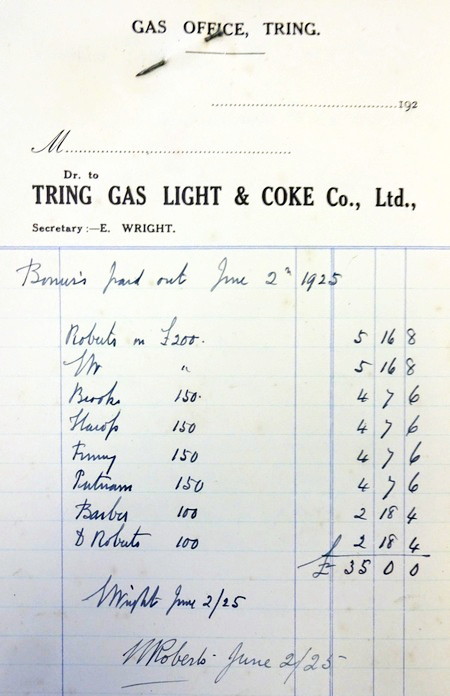

In the Company’s later years,

its workforce were able to

participate in a profit sharing scheme, paid in proportion

to their wages. |

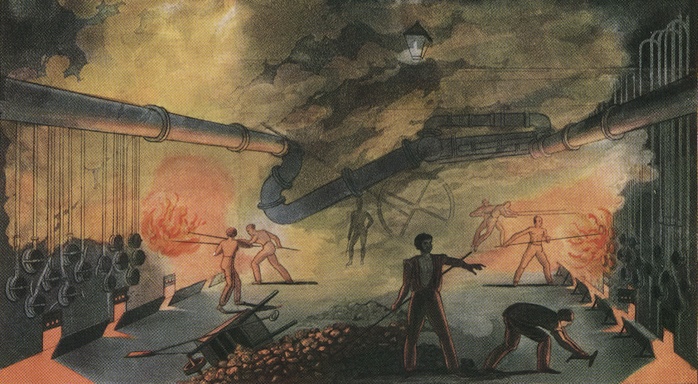

STOKERS: conditions for the manual

workers employed in early gasworks were harsh, and this was

especially true of the stokers. Their work was to load coal

into, and, following carbonization, unload the manufactured coke out of the

’retorts’

(ovens in which the coal was baked over a furnace to extract the gas ―

see Appendix 1). They also had to tend the

furnaces in hot, dirty and dangerous conditions. The following

describes the stokers’ working conditions at a typical gasworks of the

time:

“There were four stokers, whose main job was to load the retorts

with coal, discharge the coke when carbonisation was complete and

attend to the furnace. It was hot, hard, and dirty work.

The front wall of the retort settings became so hot that the stoker

had to work from several feet back, using long-handled tools.

In order to get the coal evenly spread out, the stoker had to throw

the first shovelful straight to the far end of the retort, a

distance of approximately 5 metres (16 feet) from where he was

standing. When the red hot coke was emptied from the retorts

after carbonisation it burst into flames on contact with the air and

had to be quenched with water, making the atmosphere in the retort

house even more unpleasant and difficult to work in.”

Stokers wore hats to protect their hair from sparks, but it was

too hot to wear many clothes, and of course nobody even thought

about protecting their lungs!

Despite the terrible working conditions in the retort house, some of

the Tring stokers served for many years. The Bucks Herald

mentions two. In July 1937, Mr. & Mrs. T. Brooks celebrated

their golden wedding anniversary, he having served for 49 years with

the Company, and in October 1948 Mr. & Mrs. Fred Harrop celebrated

theirs, he having served for over 30 years, partly as a lamplighter

in the Town.

Stokers drawing the retorts in a large

gasworks.

The pay and terms of service of the stokers don’t appear in the

early Minutes and it is not until the 1890s that there is any

indication of what they were. The entry for 8th May, 1894,

records that at that time only one stoker was employed, his wage

being 19s. a week. When the stokers requested a pay rise two

years later “the wages of the two stokers and the lamplighter be

raised 1s. per week for the winter months commencing the 1st week in

October.” Working hours must have been long and

unsociable, for in 1897:

“An application was received from Brooks and Finney, the gas

stokers, that they be permitted each to have one clear Sunday per

month off from the Works. After discussion it was resolved

that their application be acceded to.”

Tring Gas Company Minute Book,

9th March 1897

Despite the rigour of the gas stoker’s lot, Mr. T. Brooks (pictured with

his wife on their 50th wedding anniversary in July 1937) managed to

endure 49 years of service with the Company in that capacity.

However, by 1946 the Company was facing real difficulty recruiting

people prepared to take on this gruelling work:

“SERIOUS POSITION AT

THE TRING GASWORKS.

― The Ministry of Fuel and Power wrote calling attention of the Council

to the continuing serious position existing at the Tring Gasworks, due,

the letter stated, to the complete inability of the gas engineer (who in

the past has been compelled to carry out his own stoking) to obtain

stokers. The Works were badly in need of two, and their absence

endangered the maintenance of gas supplies to the district . . . .”

Bucks Herald, 10th May 1946

When this problem was raised at a meeting of the Tring Urban District

Council, it was agreed that German prisoners of war be put to work in

the retort house and that a letter be sent to the Ministry to that

effect, but the solution that was eventually adopted is unrecorded.

COAL

Coal was the raw material from which Tring’s gas was manufactured and

throughout the life of the Company there are numerous references to it in the

Minutes. These relate to trials to identify the best

gas-yielding coal,

obtaining quotations from coal merchants, signing supply contracts and to the cost of hauling

coal to the Works.

The earliest record of coal being bought was in January 1851, when it is

recorded that “Messrs. Rowbotham and Frederick Butcher reported that

they had agreed with Mr Alfred Penny, Coal Merchant of London, for the

purchase of 49 tons of South Peareth Coals to be delivered to Tring

Wharf at 18s 6d per ton”. Subsequently one Parker was paid £2

10s 3d for haulage to the Works. The names Mead & Bailey appear in the early Minutes ― 8th July 1852, Mead &

Bailey paid 16/4 for “wharfage of coals”; 7th September Evans

paid £1 8s 0d for “carting coals”. Mead & Bailey

were the owners of Gamnel Wharf, so it is reasonable to assume that

early coal deliveries were by canal. However, in 1859 the

Minutes refer to coal being delivered to Tring Station, and there is

no further mention of Gamnel Wharf.

As one would expect, the quantities of coal bought by the Company (and

its price) gradually increased over the years as the town’s population

grew and more people were connected to the supply, which they later used

for cooking and heating. By 1876, the modest initial order of 50

tons at 18s 6d per ton had grown to “500 tons of coal from the Wigan

Coal Company at 19s 5d per ton delivered in Wigan [railway] trucks

to Tring”. In 1885, the Company bought 700 tons of Madeley

screen gas coal at 15s 7d per ton; in 1898, Messrs Hackett & Co contracted

to supply 1,000 tons of coal at 18s 11d per ton; by 1925 the annual order

had risen to 1,600 tons and, by 1929, to 1,800 tons. Although the

Minutes don’t state it, it seems fair to assume that these quantities

equate approximately to the annual coal consumption.

Not all coal was suitable for conversion into gas ― a process referred

to as ’carbonisation’ ― and from time to time the Minutes refer

to trials of different types of coal being made to identify that which

produced the largest quantity of gas per ton. For example, in

April 1925, 4 types of coal were tested, the results being:

|

TYPE |

PRICE PER TON |

YIELD (cu.

ft)/TON |

| Low Staithes |

31s 11d |

12,800 |

| Leashbridge |

32s 03d |

12,450 |

| Barrow |

33s 05d |

12,375 |

| Old Silkstone |

32s 04d |

12,060 |

After further tests the Minutes record that the board decided to

order 1,000 tons of Barrow at 32s 11d, 400 tons of Leashbridge at

32s, and 200 tons Low Staithes at 31s 11d.

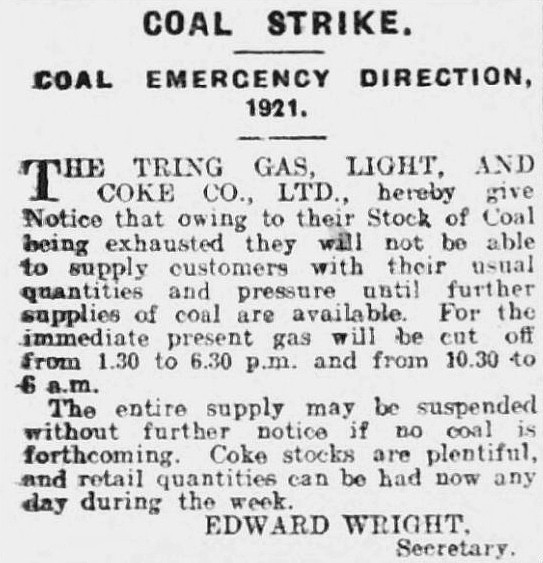

|

|

|

From the Bucks Herald, 16th

March 1921 |

Coal supplies were seriously curtailed on three occasions, which in turn

caused shortages in the amount of gas available to the town. The

first disruption was during the miners’ strike of 1912, the first

national coal strike in Britain. The strike took place at a time

when the distribution of wealth derived from the pits was

disproportionately in the favour of the mine owners. Wages were

set on a sliding scale ― when the coal price went up, wages increased

slightly; when the price of coal decreased, wages plummeted. Thus,

the miners’ goal was to secure a minimum wage. After 37 days of

disruption, and fearing widespread civil unrest, the Government

abandoned its stance of non-intervention and rushed a Bill through

Parliament, from which emerged the Coal Mines (Minimum Wage) Act (1912).

News of the impending strike caused heavy buying that in turn

caused a coal shortage, forcing up prices. At the Company meeting

held on 1st February 1912, the Secretary reported that Messrs. Foster,

the Company’s supplier, had only sent 94 tons of coal since January.

At the following meeting, 150 tons of coal having been received from

Fosters, and in view of the continuing shortage, the Secretary

was instructed to purchase what coal he could. This resulted in some 30

tons being obtained from local coal merchants together with another 10

ton of broken up coal, otherwise known as ’slack’. The directors

also decided not to light the street lamps after 24th March until coal

supplies returned to normal, but this resulted in one of the periodic

spats with the Council Lighting Committee, who insisted that their

contract with the Company had to be honoured and were not not prepared

to have any lamps unlit. The outcome was that only 9 lamps in

various positions in the town were lighted. By April 1912 the coal

position was serious, all that was available was 3 to 4 tons with local

merchants at 32s a ton and a truck at the station at 31s. However,

by June 1912 the position had returned to normal and the Company was

able to obtain 1,000 tons of coal from their supplier.

|

|

|

Bucks Herald, 3rd July 1926 |

A

further strike took place in 1921. During the First World War the

state took control of the coal industry on account of its importance to

industry. Under government control, miners’ wages, hours and

safety improved, and at the end of hostilities the miners wanted to

retain the status quo. Being unwilling to provoke strike

action, Lloyd George’s Coalition-Liberal Government retained control of

the mines until 1921, when the industry was returned to private

ownership and to pre-war working conditions. The ensuing miners’

strike lasted for three months, at the end of which they were forced

back to work on worse terms than they could have had at the start.

A further disruption occurred during the General Strike of 1926, when

the Minutes refer to the serious position obtaining coal and

great difficult maintaining gas supply, but they give no more

detail.

GAS MAINS

The Minutes makes no mention of the original extent of the

Company’s

gas mains, although from the business that later transpired it is

evident that the supply ran up Brook Street to the Robin Hood and then

along the High Street (then called ’Market Street’) to the cross roads

before turning up Akeman Street. Later evidence suggests that the

mains also extended into Frogmore Street. Then, in September 1854,

the directors decided to extend the mains to the “West End” of

the Town. A Special General Meeting of the Shareholders was called

at which this decision was endorsed, subject to the approval of an

engineer (this was the only time that such a formal procedure for

extending the mains was used, later extensions being decided solely at

Board meetings). The plan was that:

“the Company’s Mains be extended from the end

of Market Street to the Bricklayer’s Arms and from the top of Akeman

Street to the Turnpike Road at Miswell Lane.”

Minutes,

24th September 1851

In today’s terms the two extensions were to run (i) along Western Road

to the corner of Duckmore Lane (once the site of the Bricklayer’s Arms)

and (ii) from the top of Akeman Street along Park Road to Chapel Street,

and then down to Western Road. Atkins was invited to give an

opinion on the plan’s feasibility and in due course:

“A Report of Mr Atkins upon the proposed

Extension of the Company’s mains was read by the Secretary, approving of

the said Extension, when it was resolved that the Work be proceeded

with, and that in addition a 2 inch main be laid from the proposed main

by Mr Robert Wright’s along Pleasant Terrace to Mr Garnett Jones’s.

[8]

The Secretary was directed (with the assistance of the Manager at the

Works) to draw up Specifications to be submitted to Mr Atkins and then

to invite Messrs Killy, Mr Atkins, and Mr Chas Grace to tender for the

execution of the proposed Works.

It was resolved that in every case where the Consumers have Gardens

intervening between the Public Road and their Hose the Company do carry

their Services through their Inclosures towards the House to the extent

of 40 feet.

The Secretary was directed to write to the Surveyor to the Turnpike

Trustees for permission to break the Ground in order to lay the

Company’s Mains.”

Minutes,

28th September 1854

The work was to be financed by the issue of 30 new shares of £10 each,

to be offered to existing shareholders in proportion to their holdings.

Three tenders for the project were received. A Mr Crichton having

submitted the lowest bid, at £208 12s., a contract for the work was

signed with him on the 18th October. Work then commenced and

continued into the following month, during which Crichton was paid £150

in three instalments. It appears that the directors took the

prudent step of inserting a retention clause in the contract, for when a

gas leak was discovered in March of the following year, which Crichton

failed to remedy, the Company offset the estimated cost of lost gas

against the balance outstanding on the contract (the question of public

safety is not mentioned).

In September, 1857, the directors considered two possible lengthy mains

extensions.

|

|

|

In adverts for the Raleigh Light

Delivery

Van (c. 1934) the Tring Gas Company is listed

among the vehicle’s ’discriminating users’. |

The first request was from Sir Anthony de Rothschild ― who in the early

1850s had acquired Aston Clinton House ― who asked the Company to quote

for supplying gas to his house and estate. The reply was that the

Company would lay on gas and erect a gas holder for £1,150, and would

supply gas at the same price as for private consumers. Nothing

more came of the proposal, but Sir Anthony later erecting his own

private gasworks on the bank of the Wendover Arm Canal at Aston Clinton

(his relation erected a similar private gasworks on the canal bank

further West to supply Halton House).

The second proposal concerned the railway. When Tring Station was

constructed in 1837, a small gasworks was built at the south end of the

up platform to supply gas for lighting. In September 1857, the

Minutes record that the directors were aware that the London &

North-Western Railway Company was planning to rebuild Tring Station and

that the gasworks was to be taken down. As a result the Secretary

was instructed to write to Captain Huish, the L&NWR Company’s formidable

General Manager, to advise him that the directors were prepared to lay

on gas to the Station, but nothing further is recorded. In later

years the L&NWR asked on several occasions for a quotation to lay on a

gas supply from the Town, but no agreement was reached and the Station

continued to generate its own gas from a small gasworks, by then located

on the North-East side of the Station Road bridge.

Nothing further is recorded on extending the mains until November 1875,

when a considerable extension was made, although its impact appears to

have been limited to supplying gas to the residences of just two of the

Town’s better off citizens:

“A detailed statement of the cost of laying the

new Main from Brook Street to Mr. Wm. Brown’s residence [and]

from thence to the entrance of Mr Williams’ Park in the Station Road, a

distance of 1765 yards, was laid before the Meeting. The total

cost of same amounted to the sum of three hundred and forty nine pounds.

Also the Moiety of the cost of laying the new three inch main from Beech

Grove to the entrance of Pendley Park, a distance of one thousand and

seventy five yards amounting to the sum of one hundred and four pounds

nineteen shillings and seven pence was examined and approved.”

Minutes, 11th November 1875

Nothing further is recorded in the Minutes, but later business

shows that the work was completed.

In 1886, the mains were extended along Brook Street to New Mill Baptist

Chapel (dealt with in the next section) and to Tring Wharf. In the

previous year an enquiry had been made to the Company (under the Tring

Drainage Scheme) to know what their terms would be to extend the mains

to the new sewage works for lighting and to power a 1 h.p. gas pumping

engine. The Company estimated the cost at £300 and offered to do

the work if the Tring Local Board would either pay half the cost, or

guarantee gas consumption at the Works of at least £50 p.a. for 7 years.

Nothing further is recorded in the Minutes, but it is possible

that the extension to Tring Wharf, carried out in the following year,

also satisfied the new sewage works’ requirement. Then, in 1890:

“Mr Carr, Lord Rothschild’s agent, having

requested the Directors to state the terms upon which they would lay in

a new gas main to supply the new laundry house offices, now in course of

erection, was informed that this Company would lay in a main from the

present main in Frogmore Street to a point opposite the entrance to the

new laundry, using 2½ inch and 2 inch pipes now in stock at the Works on

condition that Lord Rothschild pay the Company £25 towards the cost

thereof. Mr Carr on behalf of Lord Rothschild having accepted

those terms the Secretary was directed to proceed with the work

forthwith.”

Minutes, 15th July 1890

The Rothschild laundry was on the right at the crest of Dundale Hill

where St Peters Place now is. Although a public electricity supply

to the Town lay some years in the future, Lord Rothschild installed a

private electricity generator at the Silk Mill to provide lighting for

the Mansion, the new laundry and other Rothschild concerns.

Further extensions took place during 1891:

“A new 6 inch main be put in from the GEORGE corner to a point

opposite Chapel Street and thence continued with a new 4 inch main to

the end . . . . The Secretary was instructed, after consulting Thompson,

[the Gasworks Manager] to ask Mr

Grace to give him an estimate for supplying and laying in the proposed

new Main, also an estimate for carrying out the Works, the Company

supplying the pipes, etc.”

Minutes, 10th March 1891

“Mr Grace’s tender for supplying all material, carting and laying in

the new main along Western Road, according to specification, for the sum

of £235 15s 0d was accepted, the work to begin early in June and

completed 5 weeks from the time of commencement. The Secretary to

write to the Chairman of the Local Board asking permission to open the

ground as required.”

Minutes, 19th March 1891

“As agent for and on behalf of J. G. Williams Esq., I

[Septimus

G Foulks] hereby sanction a Gas main to be put

under the new Road (Christ Church Road) extending from Parsonage Bottom

to the entrance of Mr Frank Brown’s new residence, such main being the

property of the Tring Gas Co. and they be allowed free access to the

same at any time.”

Minutes, 14th July 1891

|

|

|

Okeford |

Frank

Brown was then the principal partner of William Brown & Co., auctioneers

and land surveyors, later to become Brown & Merry. ’Parsonage

Bottom’ was the name for the dip in Christchurch Road, then the location

of a farm. “Mr Brown’s new residence” refers to ’Okeford’,

the splendid house that he built at the top of Christchurch Road, now

the site of Okeford Drive ― the house name was taken from Okeford

Fitzpaine in Dorset, from where John and William Brown originated.

In its latter days the building served as Osmington School

before being pulled down to make way for residential housing.

In following years, as the town grew, the gas mains were extended

further, but as extensions became common less details are recorded in

the Minutes.

WATCHING AND LIGHTING

The reasons for erecting a gasworks in the Town were to provide

improved street and domestic lighting ― other uses of gas lay well in

the future. To estimate how much gas would be needed for

these purposes, the directors undertook a survey of potential

customers:

“We have received promises of 150 private lights; in addition to

these, the probable consumption of Gas in the places of Public Worship,

the Silk Mill and in the public Streets will be equal at least to 60

more.”

Tring Gas Company Minute Book,

19th April 1850

The Lighting and Watching Act of 1833 was the first statute to deal with the establishment of paid

police forces in England and Wales. It enabled, but didn’t

require, boroughs to form police forces along the lines of London’s

Metropolitan Police, which had been set up in 1829. The Act

allowed groups of property owners to form committees to organise local

police forces (the ’watching’ part of the Act) and street lighting

(mainly to combat street crime) and

they were empowered to levy a rate on householders to pay for these

services. In fact Tring had recruited two watchmen some years

previously:

July 1826:

“A vestry was held ’for the purpose of considering the

propriety of establishing Watchmen in the town’, and the Guardians of

the Poor were requested to look out two of the paupers for this duty.

There were two watchmen who walked round at night, but did not call the

hours.”

From Arthur MacDonald Brown’s notes

The policing provisions of the Act appear to have been implemented in Tring

by

1836, for an article in the Bucks Herald of November that year

refers to

“H. J. Coulter, one of the Tring police” making an arrest on

suspicion of the theft of fowl; Arthur MacDonald records in his notes that “Coulter and Johnson

were the first two policemen here ― they came shortly before the railway

opened” [1837], by which time the Town had acquired street lighting:

“A public meeting of the ratepayers was held to determine whether the

Act for Lighting and Watching Parishes shall be adopted in Tring.

It was carried unanimously and the Provisions of the Act should be

carried out in the Town and the suburbs, and that there be 7 Inspectors

for the purpose, also that £105 be raised for the purpose. It was

resolved that the boundaries of the Town and suburbs be considered to

extend to Miss Miles’ house in London Road, Mr. John Mead’s house in the

Wingrave Road, Mr. W. Griffin’s house in the Aylesbury Road, the house

of the Revd. Jeffery, Aylesbury Lane, Tring Park and premises, and

Maidenhead Street.”

From the Tring Vestry Minutes for 1836

Tring’s original street lamps are believed to have been Naphtha flare

lamps, the forerunners of the nowadays widely known high pressure

paraffin ’tilley’ lamps. Invented around 1830, they were also

widely used by showmen, market-stall holders and circuses until World

War I:

“1844: Situation of lamps to be fixed ― pillar lamp in open space

near Robin Hood; Bracket lamps at Green Man; Ivy House. Wright’s; by

Bull’s Ally (Bank Ally); on James Wilson’s cottage. Mrs Mary

Tomkins & Son ordered to procure lamps and about 30 gallons of Naphtha.

Order to Overseers to raise £44 by rate upon occupiers of property

adjoining the road from Mile Post at Dunsley to Mr. John Mead’s house at

the entrance of the Town from Aylesbury.

Oct. 1845: Lamps not lighted since April 7th. Mrs Northwood’s lamp over

Rose & crown half expense of lighting to be borne by Inspectors.

Nov. 1846: Pillar lamp to be placed at Cross roads near Post Office

(Bedford’s shop) in such position as may hereafter be determined.

Meetings held in Commercial Hall.”

From Arthur MacDonald Brown’s notes

The Gas Company Minutes don’t record how many gas street lights were

erected, but by October 1850 their contractor, Atkins, reported to the

Board that the new gas lamps were nearly ready for use. The Board

therefore decided to approach the Town’s Lighting Inspectors with a

proposition:

“That the year shall end on the Second week in April 1851 if so long

required by the Inspectors, and that the lamps shall be lighted entirely

at the Expense of the Company at 42s per lamp and that the lamps be not

lighted at the full of the Moon five nights on average.”

Tring

Gas Company Minute Book, 2nd October 1850

On its

formation in 1850, the duties of the Lighting Inspectors were taken over by the Tring Local Board of Health. [9]

Although the Gas Company Minutes continue to refer to the

“Lighting Inspectors”, a Lighting Committee of the Local Board took

over the management of street lighting, and, until gas lighting was

replaced by electricity in 1928, there

were to be exchanges of correspondence (and sometimes of views!) between them and the Gas Company over

the price of gas lighting and the cost of maintaining the town’s street lamps.

Eventually, in 1861, the Company agreed a contract with the Local Board

to take charge of the town’s (then) 40 street lamps, keep them painted and

repaired, light them on 140 nights from 1st June for an average of 6

hours a night at a cost of £2 10s. 0d per lamp. But the agreement

didn’t always run smoothly and there are a number of entries in the

Company’s Minutes that record spats between the Local Board and the

Company over lamplight maintenance. For instance, in May 1899, the Local

Board Secretary wrote to the Company complaining that insufficient

allowance has been made in their half-yearly charges for “partial

lighting” (i.e. nights on which the moon was sufficiently bright to

allow the lamps to be lit for shorter periods). In their reply the

Company disagreed, pointing out that the existing agreement had been

made when there were 51 public lamps in operation, a number that had

gradually increased to 72 without any corresponding increase in the

amount charged for lighting them. This retort silenced the

Lighting Committee, for nothing further is recorded on the matter; they

should have kept quiet, for in the following year the Company increased

their charges to take account of the increased number of street lamps,

by then 75.

Gas street lamp at the junction of Akeman

Street and Park Street, Tring (courtesy Mike Bass)

For

the remainder of the life of Tring’s gas street lights, a supply and

maintenance contract ― updated from time-to-time ― between the Gas

Company and the Local Board (from 1894, the Tring Urban District

Council) remained in force. By 1922, shortly before electricity

took over from gas as the lighting agent, Tring had 80 street lamps in

operation for which the Company quoted £4 3s per lamp for gas and

maintenance.

In addition to correspondence on the operational costs of street lighting, an occasional request was received from the Council

to extend the gas mains so that additional street lights could be

provided. The following is a case in point:

Tring 9th Novr. 1885

Dear Sir

I am directed by the Board to send you for the consideration of your

Company the enclosed memorials as to the public lighting of the road

between the gas works and New Mill with a recommendation to your Company

to consider the matter formally.

I may say that the Board would be willing to erect the necessary public

lights on your Company laying the mains.

Yours Faithfully,

A. W. Vaisey

Subsequently the Council Lighting Committee offered the Gas Company 10

shillings extra per lamp per annum to supply and maintain the new lamps

for a period of five years in consideration of the Company paying for

the whole work of laying the new main.

Tring Gas Company, Feb 1st 1886

Gentlemen.

In reply to your letter of the 11th Jany. last I am directed to inform

you that the Directors of the Gas Company fear that the offer of the

Local Board will entail upon them a heavier loss than they ought to bear

and they regret a more equitable offer has not been made. But

considering that the new lamps will be a great public benefit they have

resolved to accept it and they will lay a four inch main from the Gas

Works to Tring Wharf in accordance with the wishes of the Local Board.

I am

Yours Truly

J. Amsden, Secretary

News of the project to lay the new main soon reached the ears of the New

Mill Chapel elders, but rather than approach the Gas Company they

decided to enlist the support Frederick Butcher, a leading citizen of

the town and an ardent Baptist:

15 Akeman St Tring

31st March 1886

Fredk. Butcher Esq

Chairman of Tring Local Board

Dear Sir.

On behalf of the New Mill Baptist Church I am requested to inform you

that we learn with much pleasure the decision of the Board to light the

road from the gasworks to the Tring Wharf. We earnestly hope that

you may see your way to laying a main along the new road to the Chapel

as we are anxious to light it with gas.

I am

Yours very Respectfully

Thomas Grace

Secretary

. . . . who in turn sent it forward to the Gas Company:

Tring Gas Company, April 21st 1886

Dear Sir

Your letter of the 5th Inst. containing a copy of Mr. T. Grace’s letter

to the Chairman of the Tring Local Board was duly laid before my

Directors at a meeting here last evening. And it was unanimously

resolved to comply with the request contained therein and lay a main to

New Mill Chapel.

I Am

Yours Truly

J. Amsden.

Whether the Gas Company saw any profit in so doing is not recorded, but

gaslight came to New Mill Chapel in 1886.

The interior of New Mill Chapel in the 1920s

showing the gaslights in place

|

|

|

Gas mantles |

In 1887

an important improvement was made to gas lighting with the invention of

the ’incandescent mantle’. Gas mantles are fabric items

impregnation with metal nitrates. When heated by a flame, a mantle

forms a rigid but fragile mesh of metal oxides that produces a very

bright light, much brighter than the naked gas flame that preceded it.

The gas mantle was to form an important component of street lighting

until replaced by electric lamps. Today, mantles are still used in

portable camping lanterns, pressure lanterns and some oil lamps.

GAS FOR COOKING AND HEATING.

In his unpublished notes, the late Tring local historian Ron Kitchener

commented “Many folk were frightened of ’the

new-fangled things’ and stuck to coal and wood fires, candles and

paraffin lamps even as recent as the 1960s.”

The initial purpose of a gasworks was to provide gas for lighting,

principally for street lighting but from the mid-19th century gas was

used increasingly for domestic lighting. As people had a coal fire

for heating, they generally had a coal fired ’kitchen range’ for

cooking. Although rudimentary gas

cookers had been invented during the 1820s, they were little used.

It was not until gas cookers were shown at the World Fair in London in

1851 that they began to gain acceptance, although their use at this time was

restricted mainly to more wealthy households.

By the 1880s it had become apparent that electricity would eventually

replace gas as a source of lighting and, having looked

around for other potential revenue-earning uses for their product,

gas companies began

to promote gas for cooking and heating. This coincided with the

appearance of the pre-payment (or slot) gas meter, which, together

with gas companies beginning to offer their customers gas cookers to rent,

were important steps in making gas more affordable to the wider community.

The invention of the oven thermostat in 1923 was a further

development in popularising the gas cooker.

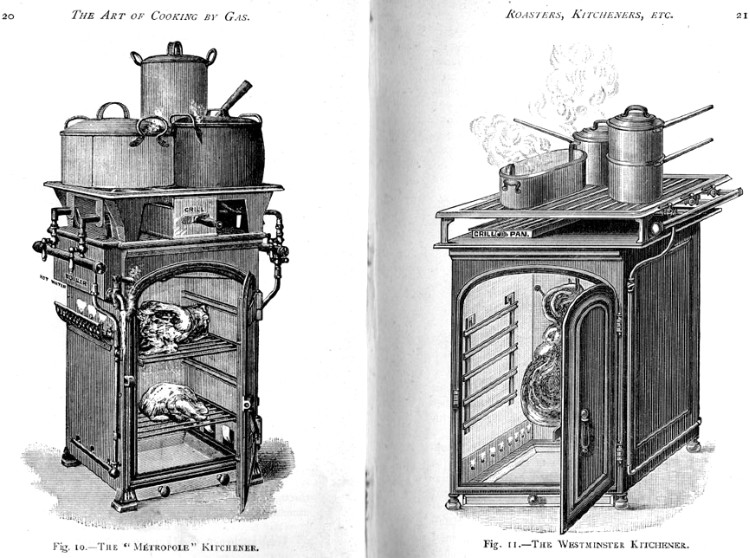

Early gas stoves by Sugg

As for gas heating, by the mid 19th century gas fires had been designed, usually

incorporating tufted asbestos heated by gas burners, but coal remained

the preferred fuel until well into the 20th century. Ceramic

radiant fires were introduced in 1905 and the efficiency of gas fires

was improved substantially in the 1950s with the development of

convector fires, which use a heat exchanger to recover heat from the

flue gasses. The big change to heating followed the Clean Air Act (1956),

which restricted the use of solid

fuel in urban areas and led to a massive increase in the popularity of

gas fires, space heaters and central heating boilers.

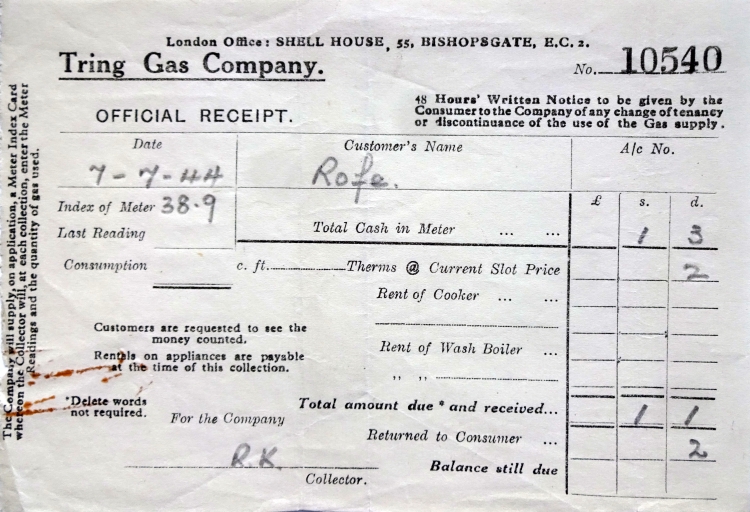

At Tring, the earliest reference to prepayment meters and rented cookers

in the gas company’s Minutes was in 1896, when . . . .

“The Secretary was instructed to order one

each of Nos 8, 9 & 10 Davis’s gas cookers and also 4 prepayment meters. Mr [Jesse] Hansford of the Grammar

School Western Road, having asked if the Company would lay on the gas to

the house occupied by him and provide a gas cooker there and on

what terms, the Secretary was instructed to inform him that the Company

would be willing to do so without charge on condition that he be

supplied with gas through a prepayment meter.”

Minutes,

14th July 1896

It appears that this innovation soon became popular, for by 1903 the load on the workforce had increased:

“Thompson the manager at the Works attended

the meeting and stated that, in consequence of the Introduction into the

Town of gas cookers and automatic gas meters, the labour in the retort

house and yards is increased, while at the same time the fixing of the

cookers, automatic meters and their service pipes had for some weeks

past taken up the whole time of Thompson’s son. Consequently an

extra man had been employed. The stokers also asked for an

increase in their wages. It was resolved that the extra man be

kept on and that the wages of the 2 stokers and the lamplighter by

raised 1/- per week for the winter months commencing the 1st week in

October.”

Minutes, 10th Nov 1903

“Company to reduce rent for gas stoves to 1/- per quarter for those

whose house rent does not exceed 5/- per week. This proved difficult to

implement, so all prepayment meter customers charged 1/- per quarter.”

Minutes, 27th May 1907

Of course a perennial problem with prepayment meters was theft of the

takings:

“The

Secretary informed the Directors that a prepayment meter in Mr Green’s

cycle shop had been broken open and the money, amounting to about 16/-

taken out. Mr Green declined to refund the amount. After

considerable discussion, it was decided not to take any further steps at

present in the hope that some precedent of a similar case may be found,

and the box of this meter be cleared weekly, which has been done since

the occurrence.”

Minutes, 10th Nov 1903

But on the other side of that particular coin, prepayment was a means of

curbing the amount of late payments and bad debts:

“The

Secretary informed the Directors that Mr John Green of Akeman Street

owed for 5 quarters gas. He was instructed to press for payment

and have a prepayment meter put in.”

Minutes, 12th Jan 1904

|

|

|

Bucks Herald, 6th October 1933 |

In later

years the Company appears to have made a more determined effort to sell/rent

gas appliances, probably encouraged by the decline in the use of gas for both street

and domestic lighting following the arrival of mains electricity in the

town in 1926:

“The Tring

Gas, Light and Coke Co., Ltd., begs to inform its Patrons that a SHOW

ROOM has been opened at their Office and Works in Brook-street, where a

stock of modern Cookers, Fires, Boilers and lamps, etc., may be seen.

An inspection of same is cordially invited.”

Bucks Herald, 5th February 1932.

In addition to promoting their new showroom, the Company also arranged

demonstrations in the art of gas cooking:

“COOKERY DEMONSTRATION.

― There have been large attendances at the Church House during the week

to witness cookery demonstrations arranged by the Tring Gas, Light and

Coke Company, in conjunction with Messrs. Richmond and Company, and the

manufacturers of Radiation appliances. The exhibition was opened by Mr.

John Bly, Chairman of the Urban District Council, who was introduced by

Mr Ed. Wright, Secretary and Director of the Gas Company. Cookery

demonstrations on the latest type of gas stove were given by Miss D.

Jaques, and a cake-making competition will be judged today (Friday).

Many modern gas appliances were on view, including stoves, fires,

geysers and modern lighting.”

Bucks Herald,

27th May 1932

“GAS

EXHIBITION. ― The gas exhibition and cookery demonstrations recently

held at the Church House by the Tring Gas, Light and Coke Co., Ltd.,

proved to be very successful. The exhibition extended over four

days, and there were two cookery demonstrations daily, given by Miss Jaques, of Radiation, Ltd. There was good attendance on the first

afternoon, when My John Bly declared the exhibition open, but the

numbers so increased at every demonstration that on the last night many

had to be turned away owing to the hall being full. The cake

competition was very keenly contested. There were 36 entries.”

Bucks Herald,

10th June 1932

The Company’s efforts to promote the use of gas for cooking and heating

against the declining use of gas for lighting appears to have borne fruit, for

at their 83rd annual general meeting held in April 1934, the Chairman

was able to report increased gas sales of 16,211,200 cu. ft against

15,144,100 cu. ft. in the previous year. The Minutes make

little reference to the Company’s accounts, but from what information

there it is apparent that revenue from appliance rental contracts

increased in each of the 5 years (incl.) from 1936 (£229 16s 5d) to 1940

(£363 5s 5d).

TRING GASWORKS’ FINAL YEARS

In 1930 the Tring Gas Light & Coke Company was bought, first by Mr W. S.

Coles of Watford and then ― it is unclear exactly when, but probably in

1935 ― by the General Gas and Electricity Company. Following an

Act of Parliament in 1936, the Tring Gas Light & Coke Company was

dissolved and re-incorporated as the Tring Gas Company, with further

powers to improve the gasworks and raise additional capital.

Further change took place in 1945 when the Company was again taken over,

this time by the United Kingdom Gas Corporation, a holding company that

controlled numerous local gas utilities including, in this area, those

at Aylesbury, Thame, Winslow and Woburn.

In 1945 Churchill’s coalition government fell and the Labour Party came to power under Clement Atlee.

The new government

soon commenced a massive programme of nationalisation. In 1948,

the Gas Act nationalised the UK

gas industry by bringing into state ownership 1,062 privately owned and

municipal gas companies. These were merged into twelve area gas

boards, each with their own management structure. These area boards became known to their

customers as the

’Gas

Board’,

a term that is still sometimes applied to British Gas. From 1st May 1949,

the Tring Gas Company was incorporated into the Southern Gas Board.

Nationalisation brought with it the construction of a gas supply grid

and more efficient larger centres of gas production. Following the completion of a gas main

from Oxford to Aylesbury, gas making at Aylesbury ceased and Aylesbury gasworks was demolished

in 1956-57. Coal gas continued to be produced at Tring

until, in 1957, the Bucks Herald informed its readers that:

“Tring

gas now comes from Oxford. For 105

[107]

years the 5,000 people of Tring

have had a gasworks, but Southern Gas now pipe from Oxford”.

[10]

Bucks Herald 19th April

1957

. . . . that was until St Ebbe’s gasworks at Oxford closed in 1960;

thereafter, until North Sea gas became available in 1971, Oxford’s

consumers received their gas from Southampton and Reading.

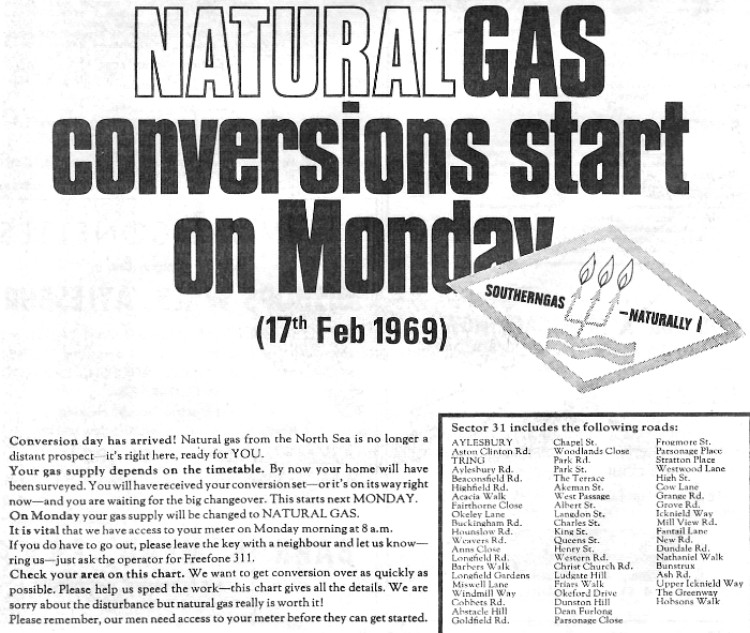

Coal gas was soon to fall out of general use. [11] Surveys had shown

that large reserves of natural gas lay under the North Sea and in 1966 the

decision was taken to convert the UK from coal gas to natural gas.

In the following year the first natural gas from the North Sea arrived

and over the next 10 years British Gas carried out a massive programme

to convert gas appliances to burn this new type of fuel. Tring

switched to natural gas at the beginning of 1969 . . . .

MAINS ELECTRICITY ― HISTORICAL NOTE

The invention of the incandescent light bulb (around 1880, by Swan in

Britain and Edison in the USA) made electric power more attractive than

gas for indoor lighting ― it was safer, cleaner and didn’t smell.

In 1881 the world’s first electric street lighting was installed in

Goldalming in Surrey; being water-driven, the town’s power station also

became the Britain’s first hydroelectric plant.

Most early electricity generating stations used steam reciprocating

(i.e. pistons driving a crankshaft) engines to generate direct current

(DC), which was stored in lead acid accumulators to provide power when

the generators weren’t running. Some of the early generating systems

described below are of this type.

Invented in 1884, the steam turbine proved to be a more effective power

source than steam reciprocating engines for producing the high shaft

speeds required for generating alternating current (AC), and steam

turbine alternators remain the main power generators to this day.

The great advantage of AC over DC is that it is possible with AC (but

not DC) to use transformers to increase or decrease the voltage, thus

allowing electricity to be transmitted over much greater distances using

very high voltages and low current flows (the amount

of power lost in transmission increases with current).

However, it wasn’t until our high-voltage electric power

transmission network, the ’National Grid’,

began operating in September 1933

that

(50 Hz)

AC became the UK standard.

TRING’S FIRST ELECTRICITY USERS

Although a public electricity supply did not become available in Tring until

1926, electricity for domestic lighting had been used by some of the

town’s most affluent citizens from the early 1890s.

Lord Rothschild of Tring Park appears to have been the first:

“TRING

― Mr. C. Burman Callow, who left Tring in July last, after four years’

residence, during which time he laid down the present extensive and

complicated plant and installation for the generation of electric light

and power at Lord Rothschild’s residence, Tring Park, rejoined his old

firm of Messrs. Laing, Wharton, and Down, of New Bond Street, London.

He has since been engaged in carrying out their contract for laying down

an installation for supplying upwards of 1,300 electric lights in the

Brompton Hospital for Consumption . . . .”

Bucks Herald, 28th December 1895

The Bucks Herald reported that electricity was used in 1893 to

light the Tring Park gate posts, although it was probably available

earlier:

“New

lampposts for Tring Park Gates ― a pair of very beautiful and elaborate

wrought-iron posts, to be fitted with powerful electric lights, are in

course of erection at the new town gates of Tring Park. They are

manufactured by Messrs. Dettilde and Co., of Archer-street,

Shaftesbury-avenue, from designs made specially, and will add materially

to the handsome wrought-iron gates lately erected by Messrs. Brown, of

Birmingham.”

Bucks Herald, 11th March 1893

Where the electric plant in Tring Park was located is unknown,

although the following article suggests it was powered by a steam engine

that needed cooling water to condense its exhaust

steam:

“Rapid growth of fish in warm water ― in the month of February last a

number of gold and silver fish were turned into the large Condensing

Pond at the rear of the Electric Light Works at Tring Park, the water of

which is always warm, the temperature varying from 65 or 70 degrees to

100, [Fahrenheit] according to the working of the engines.

The tendency of this warm water has been to greatly accelerate the

growth and development of the fish . . . . The pond, which is

round in shape, between 50 and 60 feet in circumference, and 3 feet

deep, also contains some fine specimens of Prussian carp and tench, the

former weighing over 8lbs each.”

Bucks Herald, 4th November

1893

By the final decade of the 19th century the business at Tring’s Silk

Mill, which had been running at a loss for a good many years, ceased to

be viable and it was finally closed in 1897. This rendered the Mill’s

large engine room redundant, resulting in plans being made to use it to

replace the existing electricity generating station in Tring Park.

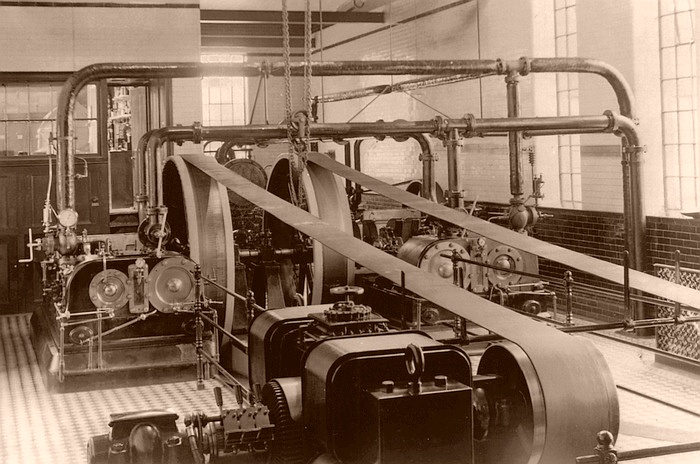

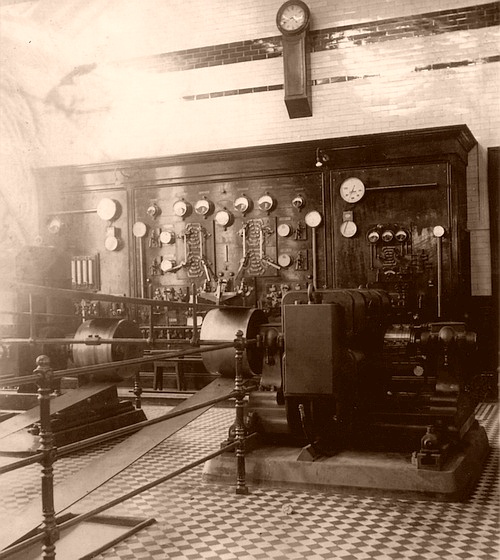

The new, sizeable, power plant was installed by Walter Thomas, a

former marine engineer, whose daughter left a memoir of her father’s

work:

“In 1895 . . . . he learned that the Rothschilds of Tring Park in

Hertfordshire were seeking an engineer to convert a large disused silk

mill in Brook Street into a power station capable of electrifying the

whole estate, a challenge to any engineer, but one he accepted gladly.

His first task was to remove two storeys from the mill, while cables had

to be laid to the Mansion, Home Farm, the Stud Farm at West Leith the

Pedigree Herd Farm at Hastoe and, later, the Museum. The power

station when completed was an engineer’s dream and your grandfather,

with carte blanche to purchase the best, was a welcome visitor to the

engineering firms of the City! The floor consisted of black and

white marble slabs, the walls of glazed tiles, the great switchboard was

of polished slate, and the instruments from Negretti & Zambra. A

vast storage room of cells and records office completed the ground

floor, while down below ground level were the boiler room and the

gigantic [water] wheel which had run the looms of the silk mill.”

The Silk Mill Power Station,

Brook Street, Tring.

Above: the steam reciprocating engines with

belt drive to the dynamos.

Below: the dynamos (DC) and switchboard.

Pictures courtesy Linda McGhee

Another early user of electricity in Tring was the Parish Church.

The generating plant ― installed in the gatehouse leading to

the Vicarage ― comprised a 4½ h.p gas engine running on coal gas

from the mains. The engine drove a dynamo, which charged a bank of

lead acid accumulators, which, once charged, could run the Church

lighting system for up to 5 hours. Electric lighting was made

possible . . . .

“. . . . owing to the advent of the metallic filament lamp,

which requires 70 per cent less energy for a given candle power compared

with the original carbon filament lamp, electricity for Church lighting

is now well within the bounds of possibility . . . .”

Bucks Herald, 8th May 1909

MAINS ELECTRICITY COMES TO TRING

It is now necessary to look at developments in Aylesbury, for it was

from there that Tring obtained its first mains electricity. (Appendix

3)

The public supply of electricity in Aylesbury commenced in May 1915.

The first power station used two 100 KW oil engine generating sets

producing

current at 110 volts

DC, across which floated a 600-ampere-hour accumulator. The

Bucks Herald described the opening of the new power station:

“The visitors entered the battery room, where Mr Turnbull

[resident engineer] explained that the accumulators, which consisted

of 250 cells of 600 ampere hour capacity ― equivalent to a supply of

about 30 horse power for ten hours ― were used for the storage of

electricity. They did not want to keep the engines on for 24 hours

for a few loads, and so they could take the electricity they wanted in

many instances from those batteries.

Proceeding to the engine room where are situated the two 150 horse-power

engines and dynamos, Mr Turnbull explained that these were run on fuel

oil which abounds in the earth in large quantities in many parts of the

world. An explanation of the switchboard followed, it being

pointed out that this controlled and measured the quantities of

electricity produced by the dynamos, and distributed it to different

parts of the town. Mr Turnbull displayed the special feeders for

Walton-street, the Market-square, Buckingham-street, and a special power

feeder out to the Tring-road district.

The Chairman then gave instructions for an engine to be started and

electricity to be put on to the switchboard. This having been

done, Councillor Adkins switched on the supply to the west side of the

High-street and to Messrs. Richards’ timber-yard, the latter

having kindly allowed the Council to connect with his up-to-date

machinery in order to give the visitors a good idea of the great

advantages of the current. Examples of the application of

electricity were witnessed in the centrifugal pump drawing water from

the canal for cooling the engines, the electric show board, and an

instance of electric cooking . . . . in the engineer’s office,

where further examples of the application of electricity were given in

heating, ozone, drilling, ironing, and lighting.”

Bucks Herald, 29th May 1915

A large

number of consumers were connected to the new system, but as the War

progressed the manufacture of munitions increased the higher demand for electric

power. By the end of 1916 the

battery capacity had been enlarged by an additional 50 per cent, but by

then the demand from the munitions factories had increased to the extent

that it also became necessary to enlarge the generating plant. New

plant entering operation in January 1918, but this too was soon found insufficient.

In August 1920, a 1,000 KW steam-driven installation was commissioned.

The new generating station was situated near the town centre by the side

of the canal, which supplied the necessary cooling water and enabled the

convenient handling of fuel from barges. By now DC had been

abandoned in favour of AC, the new steam

turbo-alternator generating a 3-phase supply at 6,600 volts.

Aylesbury Power Station: building and

switchboard (dates unkown).

In 1924, the Borough of Aylesbury applied to the Electricity

Commissioners (a Government department set up to regulate the

electricity supply industry in its early days) for authority under the

Electricity Supply Acts to extend their supply of electricity beyond

Aylesbury to outlying areas, among which were Tring, Puttenham, Aldbury

and Wigginton ― or, as the quaint wording of the application put

it:

“To authorise the Corporation to open, break up, and interfere with

all streets, roads and public places, ways, footpaths, bridges,

culverts, sewers, drains, and gas and water mains and pipes and

telegraph and telephone and other wires within the area of supply, and

to lay down, erect, maintain, renew and remove either above or

underground or otherwise electric lines, conductors, mains pipes, tubes,

wires, posts, street or distributing boxes, meters, apparatus or other

works or things required for the purpose of enabling the Company to

generate, supply, store, convey, transmit or distribute electricity

within added areas, and to confer all such other powers upon the

Corporation as may be necessary for effecting the objects of the

proposed undertaking.”

Bucks Herald, 13th December 1924

. . . . and that, in legal terms, was a watertight case

for extending the mains expressed in a single sentence! The notice

goes on to say that in Tring, the mains were to run along Western Road

from its junction with Duckmore Lane, through the High Street passing

the junction with Brook Street and extending along Station Road as far

as Hawkwell.

And so mains electricity arrived in Tring:

“Aylesbury Corporation’s scheme of extending electrical supply to the

rural areas took definite form on Monday, and Tring has the distinction

of being the first place to receive the current. The principal shops in

High-street are being supplied with electricity and many householders

are availing themselves of the advantages electricity offers. Up

to the present there are about 70 installations in Tring.

That Monday was an epoch-making day in the history of the town will be

realised more as time goes on, and the use of electricity develops.

The main line runs by Bunstrux Hill, and from there a branch line about

half-a-mile in length runs to Tring. The main line continues to

Northfield, and there are also branch lines to Aldbury, Wigginton, and

the Grand Junction Canal Pumping Station at Little Tring. The

Tring supply is controlled from a kiosk by the George Hotel, and here

the Vice-Chairman of the Council (Mr. J. Bly) . . . . performed the

simple ceremony of ’switching on’, which marks the advent of a new era

for Tring.”

Bucks Herald, 25th December 1926

The first in the area to benefit from electric power on an

industrial scale were the Chiltern Hills Spring Water Company at their

pumping station at Dancers End, and the Grand Junction Canal Company at their pumping

station at Little Tring. Until the arrival of mains electricity,

both companies relied on elderly steam beam engines to drive their

pumps:

. . . .the Chiltern Hills Spring Water Company’s pumping

station at Dancers End was reached. Here again the use of electricity

for industrial purposes was shown. Old steam pumps, still to be seen,

have been scrapped in favour of the electric pumps, which occupy less

space and are capable of a greater amount of pumping per hour. The old

steam pump, which was erected in 1879, has been superseded by an

electric motor, fixed in a well 70 feet below ground level, which runs

as efficiently as at the top and is capable of pumping a greater amount

of water.”

Bucks Herald, 26th October 1928

The water company’s

steam pumping

engine is now preserved at the

London Museum of Water & Steam at Kew. As for the canal

pumping station . . . .

“In their wisdom the canal company

last year dispensed with the old beam engine which had rendered yeoman

service for 125 years and installed a modern plant consisting of the

latest pumping apparatus. The electricity is supplied from

overhead transmission wires from Tring into the cubicle and then into

the transformers. The 250 hp pumps are running 16 hours daily . .

. . pumping to a height of 75 feet 9 inches at a capacity of 170,000

gallons per hour. The object of the pumping is to supply the canal

with water at this high point which is the summit of the Grand Junction

Canal . . . .

The Aylesbury Borough Electricity Department laid on an

electricity supply to the pumping station at 11,000 volts A.C., which a

transformer reduced to a three-phase supply at 380 volts. This was

then used to power the pump motors.

The beam of the Little Tring steam pumping

engine, replaced by electric power in 1927.

By the early 1930s, the Central Electricity Board had been set up

and many of the hundreds of small power generators were being replaced

by larger more efficient power stations (the Aylesbury Electricity

Department ceased to generate electricity in 1934, taking its supply

from the power station at Luton). The reliability of the supply

was further improved when, in 1938, the National Grid was completed

linking all key power stations nationwide. [12]

As for street lighting in Tring, during 1927 the Town Council experimented with a mix of gas and electric

street lighting. The annual cost of lighting by this means came

out at £419 2s 6d compared with an estimated cost of £366 for lighting the

entire district by electricity. Thus, at their meeting in

July 1928 the Council unanimously resolved to light the entire district

with electricity.

Tring Council’s Lighting Committee has long disappeared together with

our town’s gasworks. Today, Council Tax pays for street lighting

while Hertfordshire County Council Highways Department maintain the 115,000 streetlights in the county. All

streetlights, lit bollards and lit signs on major traffic routes are

inspected at night, at least monthly, except on roads intended for local

traffic ― which form some 60% of the UK’s roads ―

where the Department

relies on the public to report faults.

――――♦――――

APPENDIX 1

NOTES ON THE COMMERCIAL PRODUCTION OF COAL GAS

A typical gasworks vista of the 1950s.

“The processes carried on at gas-works have never occupied a very

favourable place in public opinion. The popular notions respecting

them have so long been associated with dirt, and smoke, and disagreeable

odours, that it is not an easy matter to displace these deeply-rooted

prejudices. We make no attempt to disprove, nor do we offer any

apology for, what has been very unpleasantly forced upon the attention

of those who have resided in the vicinity of gas establishments.

It is perfectly true that, through the habitual neglect of what we hold

to be an important part of a manager’s duties, the accusations relating

to dirt and offensive odours have too often been justly merited . . . .”

The Manufacture and Distribution

of Coal-Gas, Samuel Clegg (1866)

Frederick Winsor, a German, gave the first public exhibitions of gas

lighting in Britain, his aim being to promote the idea of building

centralised (as opposed to on-site) gasworks and pumping gas through

pipes to light the streets. Thus was founded the London and

Westminster Gas Light & Coke Company (from which British Gas plc

is descended), which was incorporated by royal charter in April 1812 to

become the first coal gas manufacturing plant designed as a public

utility. The Company proceeded to spread gas lighting through

London’s poorly lit streets. Their engineers, Samuel Clegg and

John Malam, were responsible for several early inventions aimed at

purifying coal gas and measuring its users’ consumption accurately.

The Gas Light & Coke Company was soon followed by other gas

utilities, the first to open outside London being at Liverpool, Exeter

and Preston, all in 1816. It is said that by 1821 no town or city

in Britain with a population exceeding fifty thousand was without gas

lighting.

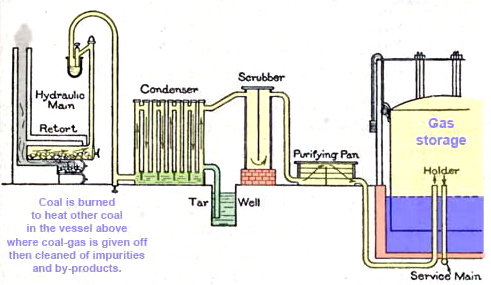

In the manufacture of town gas, a fuel, generally coal (wood, oil or coke could also be used),

provided the raw material and to minimise the

cost of delivering large quantities, gasworks were often sited

adjacent to canals, rivers or railways. Gas was extracted from the

coal by baking it in enclosed ovens called ’retorts’ in which the coal

was starved of oxygen to prevent it burning. This process produced

a crude gas that contained a number of chemical components including

hydrogen, methane and ethylene, together with unwanted substances such

as sulphur that needed to be removed by a purification process before

the gas could be released into the mains for domestic and commercial

use.

Schematic of a typical small gasworks.

The hydraulic main is a water

-filled airlock that prevented blowback of

explosive gas into the retorts

when a door is opened for recharging.

Other by-products produced during coal gas manufacturing were useful and

could be sold. These were coke (used in large quantities by

the iron and steel industries), ammonia (sulphate of ammonia is a

fertiliser), phenol (carbolic acid, a disinfectant) and coal tar.

In its turn coal tar yielded many other organic products such as

synthetic dye, creosote and drugs (e.g. aspirin) which are now produced

from natural gas or petroleum. When motor vehicles arrived and

measures had to be taken to seal road surfaces to prevent dust and mud

being thrown up by this new, faster-moving traffic, coal tar mixed with

granite chippings became a popular road-surfacing material.

A typical gasworks was divided into several sections for the production,

purification and storage of coal gas.

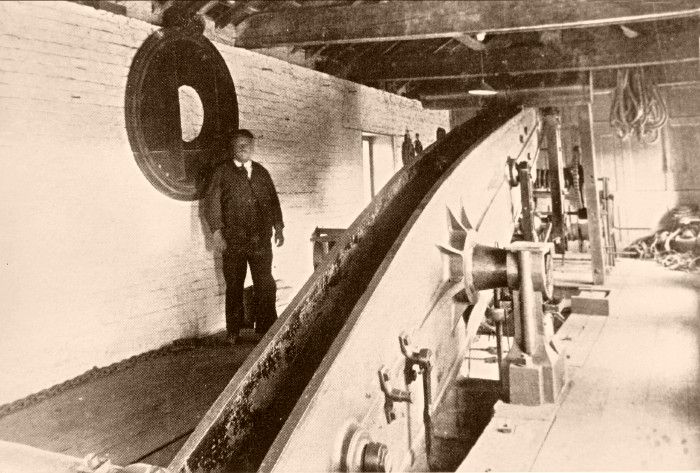

RETORT HOUSE: this contained

the retorts in which coal was heated to generate the gas. The

crude gas was siphoned off and passed on to the condenser. The

waste product left in the retort was coke. In many cases the coke

was then burned to heat the retorts or sold as smokeless fuel.

Inside a retort house.

|

|

|

Emptying hot coke from a retort. |

CONDENSER: this consisted of a bank of air-cooled

gas pipes over a water-filled sump. Its purpose was to remove tar

from the gas by condensing it out as the gas was cooled.

Occasionally the condenser pipes were contained in a water tank similar

to a boiler but operated in the same manner as the air-cooled variant.

The tar produced was then held in a tar well/tank which was also used to

store liquor.

EXHAUSTER: an impeller or pump used to increase

the gas pressure before scrubbing. Exhausters were optional

components and could be placed anywhere along the purifying process but

were most often placed after the condensers and immediately before the

gas entered the gas holders.

SCRUBBER: a sealed tank containing water through

which the gas was bubbled. This removed ammonia and ammonium

compounds. The water often contained dissolved lime to aid the

removal of ammonia. The water left behind was known as ammonical

liquor. Other versions used consisted of a tower, packed with

coke, down which water was trickled.

PURIFIER: also known as an Iron Sponge, this

removed hydrogen sulphide from the gas by passing it over wooden trays

containing moist ferric oxide. The gas then passed on to the

gasholder and the iron sulphide was sold to extract the sulphur.

BENZOLE PLANT: often only

used at large gasworks sites, a benzole plant consisted of a series of

vertical tanks containing petroleum oil through which the gas was

bubbled. The purpose of a benzole plant was to extract benzole

from the gas. The benzole dissolved into the petroleum oil, which

was run through a steam separating plant to be sold separately.

GASHOLDER: often incorrectly called a ’gasometer’,

this was a tank used for storing gas and maintaining even pressure in

distribution pipes. The gas holder usually consisted of an

upturned steel bell contained within a large frame that guided it as it

rose and fell depending on the amount of gas it contained.

A gas holder, once a common site in the

urban landscape.

――――♦――――

APPENDIX 2

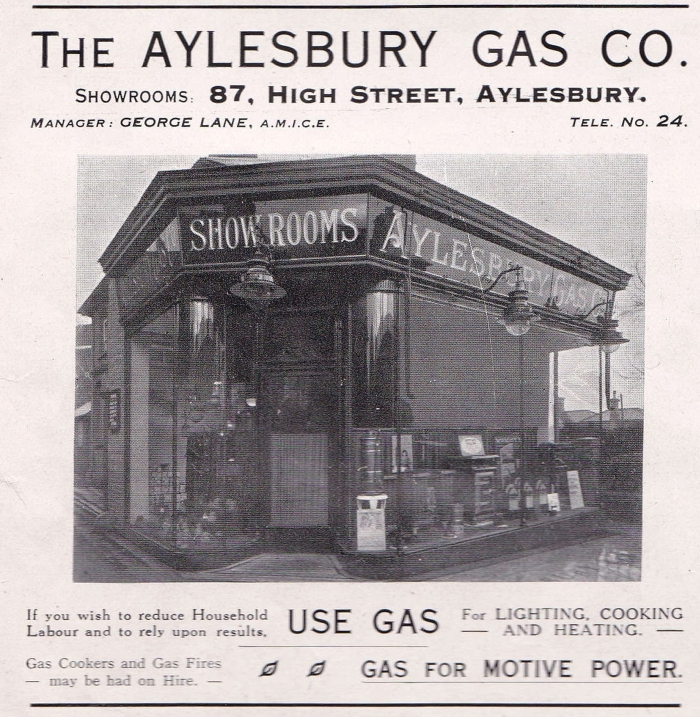

THE AYLESBURY GAS COMPANY.

ITS SLOGAN “SERVICE AND PROGRESS.”

Taken from the Centenary Edition of the Bucks Herald, 1932

Two years after the birth of the “Bucks Herald,” or, to be precise, on

May 23rd, 1834, the original Gas Company was founded to supply the town

of with gas.

There are no records to show who were the first Directors, but at a

meeting of the shareholders held on August 29th, 1861, it was decided to

form a Joint Stock Company to be called “The Aylesbury Gas Company,

Limited.” The Chairman at that time was Mr. David Reid, and the

Secretary, Mr. H. Hatten. Mr. Hatten was one of the promoters in

1834. The new Company came into being on October 2nd, 1861, with a

capital of £10,800, for the purpose of lighting the parish of

Aylesbury-with-Walton with gas. At this time gas was used almost

wholly for lighting by means of self-luminous flames. Mr. David

Reid was Chairman of Directors; Mr. J. K. Fowler was Treasurer; Messrs.

H. Hatten and Joseph Parrott were Joint Secretaries and Solicitors; and

Mr. T. Field was Works Superintendent. The annual make of gas was

10½ million cubic feet.

The make of gas gradually increased year by year, and in 1877 Mr. George

Lane joined the Company as Manager, when the make of was 19½ millions.

In 1883 gas cooking stoves were supplied to consumers on simple hire.

In 1834 Mr. Frederick B. Parrott was elected Secretary in succession to

his father, Mr. Joseph Parrott, and in 1897 Mr. Francis G. Parrott

succeeded Mr. Frederick, and in 1907 he was succeeded by Mr. Francis H.

Parrott.

The advent of the incandescent mantle was thought to be a mixed

blessing, as it was anticipated that the sales of would fall owing to

the extra light given by the mantle. This proved to be otherwise,

as more people used gas for lighting and cooking.

In the year 1901 a new process of making was introduced, namely, a

carburetted water plant, which enabled the Company to postpone the

erection of another gasholder for storing the gas.

An undated picture of the Aylesbury Gas Showrooms.

George Lane became Manager of the Aylesbury

Gas Company in 1877 and remained in that role until he retired in 1920,

being superseded by his son.

In 1904 it was decided to dissolve the Company and re-incorporate it as

a statutory undertaking, and in 1905 an Act of Parliament was passed

giving the Company power to raise capital to the amount of £90,000 and

to supply gas to the villages of Bierton, Stoke Mandeville and Aston

Clinton. At this period, owing to the demand for gas the large

gas-holder had to be built and the manufacturing plant enlarged, the

annual make of gas being 50½ million cubic feet.

From this time there was a steady increase in the sale of till 1918,

when it became necessary to build a more up-to-date method of making

coal gas. Vertical retorts were installed, and in 1921 the Company had

to seek further powers to purchase the Wendover Gas Company and supply

gas on the therm basis instead of “candle power." The plant at Wendover

was dismantled and supplied by a new main from Aylesbury.

The general strike in 1926 was the worst period the Company has

experienced. The foreign coal which had to be used badly damaged the

manufacturing plant, causing unnecessary repairs, and over £4,000 had to

be paid extra for coat during this time. The old carburetted water gas

plant had to be replaced by the latest type of plant, which, although

occupying the same space, is capable of making three times more gas. The

Company managed to “weather” the storm, however, and is still making

progress, especially in cooking and heating. Over 700 cookers have been

sold during the last five years.

It is interesting to note that owing to the long lengths of main

necessary to supply the districts, only three million cubic feet of gas

is used per annum on each mile of main, compared with some London

Companies, where, with more houses, the consumption is as high as eight

or nine million cubic feet.

The rates and taxes paid in 1861 were only £40, compared with £1,500 at

the present time.

The annual make of gas is now 92 million cubic feet.

Although 98 years old, the Company is still in “Service” and in step

with “Progress."

Mr. G. Ball, the Chairman, has been a Director for 23 years.

Mr. J. H. Coales, the Secretary, succeeded Mr. F. H. Parrott in 1917,

when Mr. Parrott became a Director.

Mr. Frank Mitchell, the Genera! Manager, was appointed in 1926.

――――♦――――

APPENDIX 3

AYLESBURY’

S ELECTRICITY UNDERTAKING.

Taken from the Centenary Edition of the Bucks Herald, 1932

The municipally-owned electricity undertaking of Aylesbury is one phase

of local commercial activity upon which the town has reason to be justly

proud. its advancement and expansion since its inception in 1915 has

been such as to make Aylesbury a by-word in the electrical world, both

in this country and abroad. It has also given the Aylesbury

Corporation the distinction of being pioneers of rural area

electrification, a movement which, under the aegis of the Electricity

Commissioners, has now been extended to all parts of the British Isles.

Moreover, the Aylesbury undertaking was the first to experiment with and

adopt the use of tar oil with Diesel engines, this step being taken

during the war in an endeavour to restrict the consumption of oil

transhipped from America. The steel transmission lines which take

the current to the countryside surrounding Aylesbury, and what is known

in the trade as the Aylesbury pole, both of which have come into

much-favoured use far and wide, also are the innovations of the

Aylesbury undertaking and of Mr. W. A. Turnbull, who has been the

Borough Electrical Engineer throughout.

Some idea of the increasing demand upon the Aylesbury undertaking can be

gauged from these facts. The original capital was £21,000, and it

is now over a quarter of a million pounds; the units sold increased from

a quarter of a million in 1915 to two million in 1924 and to eight

million to-day; when the war ended the consumers numbered 250, and now