|

. . . . AND THOSE AROUND TRING

CHAPTER XII.

BRILL POST

MILL |

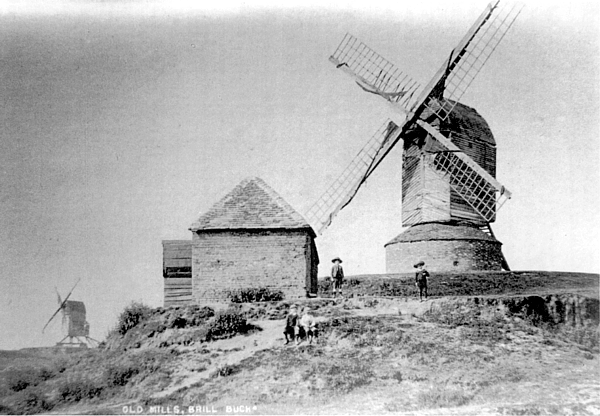

Fig. 12.1: Brill post mill

|

The old post mill at Brill stands on the ‘Common’, a promontory commanding the most magnificent view of the Vale of Aylesbury.

When taken

together with a look around the charming village of Brill, these are added

incentives to visit this particular windmill.

“There appears to have been a rectory manor

of Brill, the rector holding assize of bread and ale for his tenants

in 1276. The manor had a mill in 1086. Two centuries

later a windmill was built here of timber from Bernwood Forest,

probably on the site on which John de Moleyns, about 1345,

constructed another with oaks felled in his demesne woods.

From that time until 1733 a windmill appears amongst the

appurtenances of the manor, of which the ancient windmill now

standing may be the survival.”

Victoria County History — A

History of the County of Buckingham: Volume 4.

The earliest of the mills to which this extract refers were

either watermills or mills driven by animals. By 1345, the

windmill had arrived in Britain and that “built here of timber

from Bernwood Forest” [17] was

probably the beginning of a legacy of wind milling at Brill that

lasted until 1924, when the post mill that stands today closed for

business.

Judging by the partly obliterated inscription R.C.E. -68-I.C.

carved into a beam on its meal floor, Brill post mill was

erected by the millwright Rex Carolus for I.C. (possibly Isaac

Cummings) during the 1680s:

“Background

research and building recording carried out in May and June 2006 by

Bonwick Milling Heritage Consultancy. Dendro-dating obtains a

felling date of winter1685/6 for timber from the breast beam,

suggesting that construction of the mill took place in 1686, with 2

subsequent datable phases of repairs and alterations. Building

recording suggests a total of 4 phases of repairs: about 1725 when

mill was substantially rebuilt, 1757 when mill was again

substantially rebuilt [18],

1760 or later and in the mid-19th century.”

Buckinghamshire County Council.

Fig. 12.2: another post-mill

once stood on Brill Common. Built in 1634 and latterly known

as Parson’s Mill, it stood on the opposite side of the road to the

mill that stands today; in the photograph above it can be seen in

the background. Parson’s Mill was struck by lightning in 1905

and demolished in the following year. The mound (‘tump’) on

which it stood is still clearly visible. Brill post mill

received its roundhouse in 1865. In poor condition, it was

removed in the 1930s, rebuilt in 1950 and again in 2009.

The last of what must have been a long line of millers was Albert Nixey,

who took over in 1911 and used it to mill wheat until 1919,

although it is believed that he continued to mill barley for animal

feed for a further five years. Mr. Nixey described his mill in

the following terms:

“The centre-post is square at the base with

chamfered corners, and measures 9 feet round its sides; higher up it

is rounded and 5½ feet in circumference, diminishing to 4½ feet

above. The bottom part of the post used to be open to the

Common; a wall was built round it and roofed in 1864. |

|

|

|

|

Fig. 12.3: “the

centre-post is square at the base with chamfered corners.” |

Fig. 12.4: “higher up it is

rounded and 5½ feet in circumference, diminishing to 4½ feet above.” |

|

The bottom floor of the mill itself (16 feet by 9 feet 3 inches)

contains the bin into which the flour runs, and a recently-placed

oat-crusher. To make way for the band which drives the

last-named machine, the ‘16,’ of the date ‘1668,’

boldly carved on at tie-beam which supports

the upper floor, has been barbarously cut away. On the floor

above are the stones, one pair of burrs for wheat, and one of Peak

stones for barley. There is also on this floor a

wheat-dressing machine of a modern kind; a slanting box has a wire

screen throughout its length; inside this a spindle carrying brushes

revolves rapidly and brushes the fine flour through first, then the

toppings, and lastly the bran. |

Fig. 12.5: brake wheel,

wallower and millstones. On top of the left hand stone case is

the hopper, containing grain

which flows down the shoe into the eye of the stones to be ground.

The bell alerts the miller when the hopper runs low.

Fig. 12.6: interior of the

mills wheat dressing machine. It is missing its screens (for

explanation, see fig. 13.3)

|

The sails are of the old type with

sail-cloths, which are set by fastening one end to the extremity of

the sail and unrolling it from the ground; the sails are each 27

feet long and 5 feet wide, and in at good wind they will grind one

sack of barley in an hour with one pair of stones. In this, as

in all wind-mills, the main driving wheel is keyed to the sail-beam;

the outer rim of this great wooden wheel is acted upon by a curved

piece of iron in the manner of a hand-brake. By releasing the levers

which control this brake the mill is started.”

From In Buckinghamshire, by G. Elland

(1923) |

Fig. 12.7:

massive oak

windshaft, wooden brake wheel and wallower (for explanation, see

fig. 3.8)

|

|

|

|

Fig. 12.8: Brill

post mill in the 1930s. |

In 1928, the mill, by then in a poor state of repair, was offered

for sale . . . .

|

“. . . . and was bought by Major H.

L. Aubrey-Fletcher, the present lord of the manor, and has been

handed over to Trustees . . . . Sufficient funds were raised by

public subscription for the mill to be put in good order.

Funds are now required for a sufficient endowment to cover the small

cost of upkeep. The fee charged for viewing the interior of

the mill, together with the proceeds of the sale of s descriptive

leaflet, are devoted to the purpose. The brick roundhouse that

stood when the mill was surveyed by the Royal Commission on

Historical Monuments has been removed since then. The post has

been strengthened and rendered secure, and the ladder has been

removed, otherwise the mill is unchanged, and presents an excellent

example of mediæval mill economy. The four sails carried

canvas cloths which were furled from the ground according to the

strength of the wind.”

English Windmills, Vol. 2, by

Donald Smith (1932) |

As anyone who lives in an old mill soon discovers, the cost of its

upkeep is by no means trivial and requires a deep pocket:

“Brill’s Famous Windmill — A 17th century

windmill at Brill, one of Buckinghamshire’s historic landmarks, is

to be taken over by Bucks County Council, who will be responsible

for its future repair, maintenance and management. The mill is

included in the inventory of historical monuments in

Buckinghamshire, which the Royal Commission on Historical Monuments

selected as especially worthy for preservation. In 1929

Alderman Sir Henry Aubrey-Fletcher bought the windmill to save it

from destruction, and since then it has been maintained by trustees.

The only fund available to the trustees has been interest on £70

invested in railway stock and the infrequent sixpences of visitors

to the mill. Mr. Rex Wailes, an expert on windmills, has

advised that it will not be possible to save the mill much longer on

the present funds, and in view of this the County Planning

Committee, satisfied that it would be desirable to preserve the

mill, recommended Bucks County Council, meeting in Aylesbury

yesterday, to accept voluntary conveyance of the windmill together

with the invested funds of £70, and to undertake its future repair,

maintenance and management.”

The Bucks Free Press, 28th

February 1947

Windmills are particularly vulnerable to the ravishes of the

weather, and a mill of all-wooden construction particularly so.

By 1947, Bill windmill was again in need of urgent attention when a

storm took off one of its sails — which in turn split the

brake-wheel — and damaged the outer fabric of the mill, while

other repairs were needed to the mill’s machinery and internal

structure which in places had fallen victim to woodworm. The

work was carried out by a team led by the windmill author Stanley

Freece. [19] Probably the most evident external feature to

come out of this work was the restoration of the roundhouse, the

original having been taken down when repairs made in the 1930s.

In the immediate post-war years, when building materials were in

short supply, Freece was fortunate not only in obtaining the

services of a retired bricklayer to carry out much of the work, but

being given

gratis the necessary bricks from a kiln that had been

demolished when the last of Brill’s many brick and tile yards

closed. Others also contributed to the restoration. The

new roundhouse was completed in 1950 and, according to Freece, the

restoration of the mill’s interior was completed with a liberal dose

with creosote.

In 1967 the Council installed a structural steel framework to help

support the mill’s ancient timber frame, but as a result it

can no longer be revolved on its post to face the wind. |

|

|

|

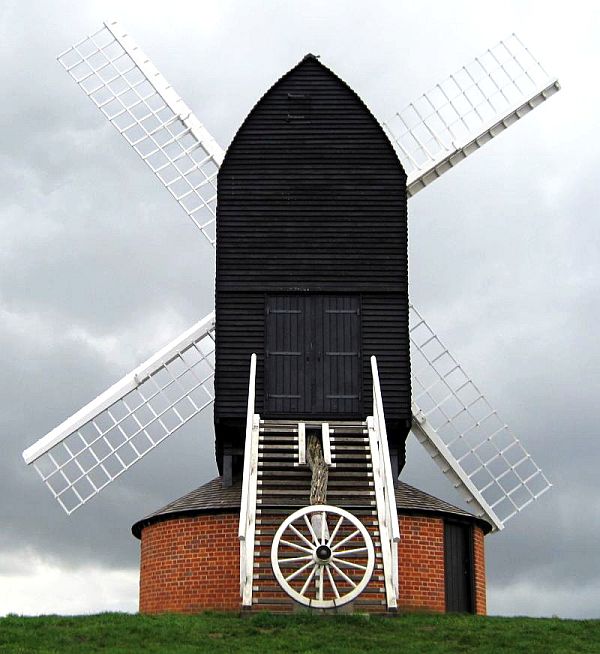

Fig. 12.9: Brill post mill,

showing the new roundhouse

and the tail pole, used to

wind the mill |

Fig. 12.10: the roundhouse roof is tiled with cedar

shingles

set on sarking boards |

|

By the turn of the Millenium,

leakage and weathering was causing timber decay, to the extent that

the structural integrity of the Grade-II listed mill was placed “At

risk”. The Brill Windmill Management Group was established in

2007 to help plan a restoration project and to seek the necessary

funds. With funding of £280,000 from English Heritage and

Waste Recycling Environmental Limited, full repair could go ahead.

Work commenced in 2008, during which the need to remove the trestle

timbers required holes to be cut through the roundhouse walls.

This revealed that the bricks and mortar used in the 1950 rebuild

were of poor quality — in fact, the surface of some of the external

brickwork was flaking. The roundhouse could not therefore be

dismantled and its bricks recycled, and a new roundhouse had to be

built.

Preservation work was completed by July 2009. The mill is now

structurally sound and is again open to the public.

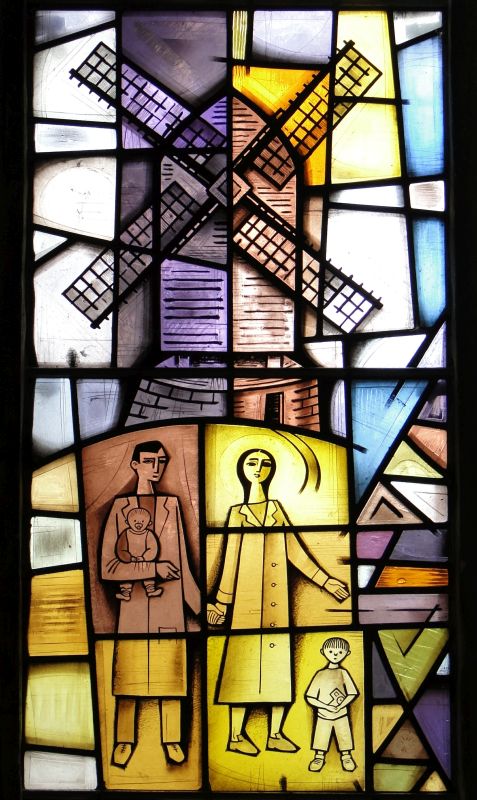

Fig. 12.11: the

Millenium Window depicting the mill in stained glass.

Stewart Bowman (1999), All Saints Church, Brill |

――――♦――――

CHAPTER XIII.

|